Project #1: Tower Analysis by PVElite

This analysis is for a CS tower...

Download analysis ReportProject #2: Horizontal Vessel Calculated by PVElite

This calculation is for a CS horizontal vessel...

Download calculation ReportProject #3: Tubesheet Calculated by UHX

In this tube and shell heat exchanger design...

Design data:

Shell side: Design pressure: 100 psi; design temperature: 212F; mean metal temperature along shell length (assumed): 180F, C.A.: 1/16″.

Tube side: Design pressure: 300 psi; design temperature: 295F; mean metal temperature along tube length (assumed): 248F; C.A.: 1/16″.

This show focuses on how tubesheet is calculated to UHX by PVElite. Therefore, nozzles and supports are not included in the model.

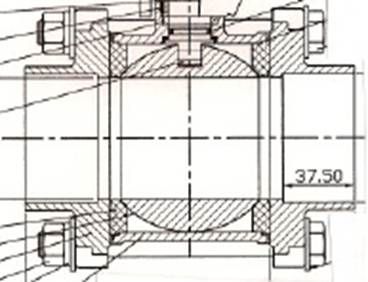

Project #4: Valve to be Calculated by ASME Code

Design conditions:

Design code: ASME Section VIII-1, 2007 ED.

MAWP: 150 psi

Design temperature: 200F

MDMT: -20F

Corrosion allowance: 0

Hydrotest pressure: 195 psi

This design can be calculated by code rules. Valve body is calculated as shell with opening verified by UG-37. End flanges are checked by App. 2. For CRN registration purpose, additional documents submitted are:

You can save dollars if designs are done to B16.34...